By Andy Alvarez and Bob Cullivan, Trident Dental Laboratories

Partially or fully edentulous patients comprise nearly half of the aging patient population, and this age group is projected to triple by the year 2005. While the fabrication of dentures that provide a secure fit and function is critical, maintaining a natural-looking appearance remains a priority for today's esthetic-conscious patients. Since its introduction in the 1950s, Valplast has been fulfilling the demands of both the clinician and the patient as a more attractive and fully functional alternative to traditional metal partial dentures.

Valplast is a flexible base resin ideal for partial dentures or unilateral restorations. The biocompatible nylon and thermoplastic resin of Valplast provide the perfect degree of flexibility and stability when processed and finished to the recommended thickness. The color, shape, and design of Valplast partials blend seamlessly with the natural appearance of the gingival tissues, making the prosthetic virtually invisible. The strong, durable plastic snaps securely and comfortably into place around the existing natural dentition and gingiva. The strength of the nonallergenic plastic eliminates the metallic taste and enables the partial to be fabricated thinly enough with nonmetal clasps to avoid the bulky feeling often encountered with ugly, bulky traditional metal partials.

FastTrack Valplast

If you currently prescribe Valplast or are considering incorporating it into your restorative treatments, the following key components will enable our technicians to fabricate your Valplast case efficiently and accurately.

Patient evaluation

The Valplast fabrication process begins with a thorough evaluation of the patient's restorative requirements. Both the clinician and the patient should actively discuss the treatment options that will meet the patient's needs (fig.1).

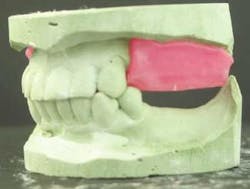

We use a cast sub-frame to provide support to the material, especially on cases with large edentulous areas. The frame is placed on the lingual with the facial clasps set into the Valplast material for added esthetics (fig. 2).

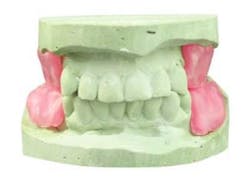

For best results, allow adequate occlusal clearance. Unlike traditional acrylic partials that utilize a chemical bond between the teeth and the base, Valplast relies on mechanical retention. If there is not enough room to place retention holes in the teeth, they can become displaced (fig. 3).

null

null

null

Impressions

There is little or no tooth preparation needed to fabricate a Valplast partial. Our laboratory requires an upper and lower impression (or models and bite registration or bite blocks) along with the desired shade. Alginate is the ideal impression material for most Valplast cases (fig. 4). However, polyvinyl siloxane (PVS) also is acceptable.

With this exact replica, a counter model, and a proper bite registration, technicians can focus on the survey and design for clasp positioning. This procedure also highlights the patient's existing undercuts and soft-tissue ridge condition for proper block-out.

Choose an adequate impression tray (Border-Lock®) or a custom tray that is rigid. Our technicians can fabricate a custom tray, which fits the individual patient's mouth. Clinicians should be advised that this additional step will require several patient visits (fig. 5).

null

null

Wax bite

Trident Dental Laboratories can provide a standard wax bite rim to facilitate the bite registration, or clinicians may provide their own. For distal extension cases, a wax bite rim is essential to the proper fabrication of the Valplast partial (figs. 6-7).

null

null

Shade selection

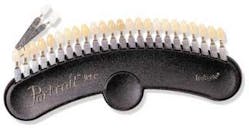

The desired shade selection and preferred teeth (e.g. Portrait IPN) should be noted on the prescription form. Valplast partials are available in several basic shade categories including light pink, medium pink, and meharry (ethnic), that blend seamlessly with the natural appearance of the gingival tissues. Generally, acrylic teeth are used with the Valplast partial. However, choosing Portrait IPN teeth will provide patients with superior dentures — superb for esthetics, and they wear like natural teeth. Portrait IPN teeth have excellent mamelon development and natural, lifelike contours. They are available in the 16 popular Vita® Classic colors as well as enhanced Bioform® Base 8 shades (figs 8-9).

null

null

Wax setup/try-in

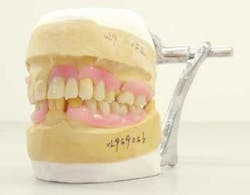

We prefer to do a wax setup/try-in to establish the correct bite and allow for custom arrangements or adjustments to the teeth prior to processing. The wax setup/try-in stage is an important step in the fabrication process and enables the clinician to double-check the shade accuracy and the setup arrangement — midline, vertical dimension, and centric occlusion (figs. 10-11, see page 58).

null

null

Process stage

Upon receipt of your case in our laboratory, the technician will make any necessary minor adjustments and proceed to the final processing stage (figs. 12-13).

null

null

In-office adjustment and patient care

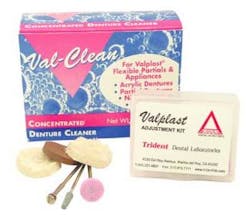

To reduce obstructions in the Valplast partial, adjustments may be performed in your office. We recommend rubber wheels and rubber points. Rubber wheels will provide you with smooth results, especially if adjusting the periphery edges. Rubber points are ideal for accessing undercut areas. Do not use carbide burs because they have a melting effect on the Valplast material. For minor chairside adjustments, a kit is available from Trident which includes Cratex wheels, green and pink stones, buff wheels, and instructions.

Patients should clean their partial on a daily basis to remove any tartar or stains. Specially formulated cleaning solutions are available from Trident to clean Valplast partials (figs. 14-15).

null

null

Expect quality

To date, more than 200,000 Valplast cases have been fabricated by Trident Dental Laboratories. Based on this experience, Trident offers clinicians a lifetime guarantee against fracture with every Valplast partial. Every case is inspected to ensure that each prescription is followed and that the quality meets your expectations as well as those of your patients.

For more information on the fabrication of Valplast partials, call Trident Dental Laboratories at (800) 221-4831.

Andy Alvarez is the Diagnostics Manager and Bob Cullivan is the Director of Quality Control for Trident Dental Laboratories.