Envisioning the future with LEDs

Redefining dental education with The Hornbrook Group

Introduction by David S. Hornbrook, DDS, FAACD. Story by Dr. Ron Ritsco

As the trend continues toward increased esthetic dental procedures, the advancement of materials and techniques will follow. The evolution of esthetic dentistry, both in the materials themselves (such as less-technique sensitive bonding agents to more lifelike composite resins) and the influence from technology (such as digital applications to lasers), will profoundly affect the manner in which we practice forever.

One technology that has shown major advancements in the past few years is that of resin polymerization systems. The current generation of the light polymerization units, i.e. curing lights, is a far cry from the original ultraviolet light polymerization units of the late 1970s. The newer lights not only cure deeper and faster, they also offer many other benefits such as different modes of polymerization, optional light guides, and portability.

The portability factor is a major advantage because we no longer require large "base" units for our lights that take up valuable room on our operatory countertops. Portable lights also offer the advantage of being able to move from room to room to use as a second light when polymerizing multiple units at one time, or when an auxiliary or hygienist needs to polymerize sealants in an operatory that wouldn't normally have a permanently stationed light. This in itself would offer the opportunity for the dental office to have less lights in the office, yet still be more efficient.

The successful trend toward portable lights has been made possible by the introduction of the LED (Light Emitting Diode) instead of traditional halogen bulbs as the source of the correct wavelength light to polymerize composite resins. The LED requires minimal electrical current, thus small batteries can be employed. The LED also does not overheat (so noisy and bulky fans need not be utilized) and does not degenerate with time, so bulb replacement is not necessary. Although the use of the LED in composite resin curing lights may seem like the panacea to solve all our previous curing light dilemmas, not all the LED lights on the market today are identical and not all light-polymerized materials will benefit from this technology.

Join Dr. Ron Ritsco as he discusses exactly how these LED lights work, their advantages, and a few of their limitations. Anyone thinking of adding this exciting technology to their restorative armamentarium can benefit from understanding the LED lights and asking the right questions before making the purchase.

Introduction

Over the past decade, light polymerization devices have come and gone. The gold standard for the polymerization of camphoroquinone-based composite materials has always been the halogen-based system. Halogen bulb and filtration technology have greatly improved to generate tremendous amounts of energy in the appropriate wave ranges we need in our dental practices. Current halogen systems can consistently put out 1,000-1,400 mW/cm2 in the wave range of 380-600 nm.

Recently, LED (Light Emitting Diode) technology has come to the attention of the dental industry, and that has resulted in a frenzy of launches of new LED-based polymerization units.

What have been the trends?

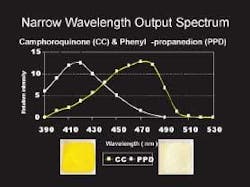

If we consider the energy range we require, we can simply look at the wavelengths of energy needed to polymerize a camphoroquinone (CC) initiator-based resin system having peak sensitivity at 450-470 nm (Figure 1, above). What is most interesting about today's composites is that they are no longer just a CC-based system. CC has a tendency to yellow the restorative material. As seen in Figure 1 (above), new more esthetic or whiter composites have an additional light-activated agent called Phenyl-propanedion (PPD). This is sensitive in the lower range of light output with a peak at 410 nm.

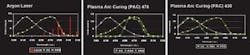

If you consider the output range of the halogen bulb, it is obvious that this is ideal to polymerize both of the currently used initiators (Figure 2, above). Unfortunately, attempts at finding other light sources to polymerize these agents have led to significant problems in under polymerization of the restorative materials. Figure 3 (above) shows various light sources and their output ranges specific to CC and, in most cases, not affecting the PPD required energies. These categories of lights include the laser and plasma arc systems. Plasma arc technology made an attempt to address this issue but never could produce outputs that polymerize both initiator systems. When PAC technology finally addressed this issue, excessive heat output occurred at common curing time requirements that could generate pulpal temperature increase that may be harmful to the pulp's vitality.

What is an LED?

An "LED" is the abbreviation for Light Emitting Diode. LED emits light resulting from a combination of two specially treated or "doped" semiconductors being layered and a small voltage being applied. Figure 4 (right) shows that an LED is just two conductor plates that, when electrical energy is added, will reflect the color or the substrate and output a light energy in a specific range. For instance, if we need an output in the range of 450 nm to polymerize a CC-based resin system, simply use a substrate that will reflect light in that range. The most common examples of LED systems are the newer intersection lights and many of the new automobile tail light systems.

Facts about LED curing lights

- LEDs are more efficient than current halogen-tungsten bulbs within the 400-500 nm range.

- Halogen units — Have an electrical input power of 100 Watts (100,000 mW) and provide an intensity of 1,200+ mW/cm2 (400-500 nm)

- LED units — Research demonstrates that LEDs need only 15 Watts (15,000 mW) of input power to achieve an intensity of 1,000 mW/cm2 (440-490 nm)

- Lower input power requirements make battery-powered units more practical and easy to use chairside.

- No light filters are needed to provide blue light within the "targeted" wavelength range (current LED unit emission is 400-490 nm).

Potential strengths of LED curing lights

- Longer-lasting, consistent light source

- LED 10,000 hours vs. Halogen 40 hours

- Smaller physical light source size, allowing for lighter, ergonomic, slim-line designs

- Lower input power requirements can allow for reliable battery powered operation.

- Depth of cure comparable to halogens when using a second-generation LED system.

First-generation vs. second-generation LED lights

First-generation LED lights

- Low-intensity

- Less than 400 mW/cm2

- 40-second practical cure time

- Less penetration through microfill composites and darker or opaque shades

- Narrow wavelength output spectrum

- Limited capability to cure all dental materials (400-500 nm)

- Minimal heat output

Second-generation LED lights

- High intensity

- Greater than 600-1000 mW/cm2

- 20-second cure possible

- Good penetration through all types of composites and ceramics

- Broad spectrum wavelength output spectrum (390-490 nm)

- Capable of curing all types of dental materials

- Heat generation like that of halogen systems

Distance from the restoration

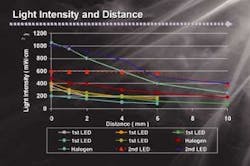

"The ideal distance between the light emission window and the composite is approximately 0.5-1mm. With a distance of 6 mm, the intensity or irradiation is reduced by up to 50 percent."1 In our testing, only the high-output halogen systems and the second-generation LED systems did not have a significant tailing off of the output intensity.

- Pires JAF; Cvitko E, Denehy GE; Swift EJ Jr:

Effects of curing tip distance on light intensity and composite resin microhardness; Quintessence Int 24, 517 - 521 (1993)

Questions to ask your sales representative about LED curing lights

The future is bright for LED technology. However, you must be sure that the LED you are about to purchase meets all the criteria crucial to have long-term clinical success in your practice. We know that the high-power, halogen type of energy will provide you with the appropriate power and intensity to achieve clinical success with the various light-initiated materials used daily. If you are ready to move ahead and be the first to offer new technologies such as LED polymerization systems, ask the following questions:

What is the output spectrum of this LED system in mW/cm2?

Answer: We have an output that will cure most composites with Camphoroquinone as the initiator system. This LED also has a broad enough spectrum to cure the more esthetic composites that require wave ranges other than those used for CC.

What is the spectrum range of your LED light?

Answer: 390-490nm

Does this LED curing light have the intensity to cure most materials in 10 seconds?

Answer: Remember, we would like to have at least 600mW/cm2 and 1000mW/cm2 for shorter curing times. Also remember that we need to penetrate 1-4 mm of ceramics or resins when cementing indirect restorations.

Does this LED curing light generate heat the way halogen curing lights do?

Answer: Usually less than that of the halogen light, but when higher power outputs are used the heat is similar to that of the halogen systems that have been proven safe by several testing centers, including CRA.

Are there variable tip sizes available for your LED system?

For various applications, we need specialized oversized or pinpoint-sized tips. Some offer this and some do not.

Summary

When using a first-generation LED polymerization system, the low-intensity levels of the battery-driven systems require the traditional 40-second curing times (opaque/darker shades and microfills may be longer). This is also true for the older generations of low to average output Halogen systems. The narrow spectrum output is comparable to the first plasma arc curing lights and argon lasers that did not reliably cure all materials containing the new more esthetic initiator like PPD. Second-generation LED systems have addressed these issues and operate with more power and consistency. Second-generation LED light sources can generate broad spectrum wave ranges resulting in high-power halogen-type curing potentials.

Hornbrook Group preferred

- LED lights must be of the newer second-generation that can generate a 30+ second continuous output at 1000 mw/cm2 of energy. Ask your local rep for a recommendation and ask the questions.

- LED systems that are generating acceptable continuous outputs at levels comparable to the high-powered halogen systems must have the availability of specialized tip selections. A TACKING tip for the TACK and WAVE technique developed by The Hornbrook Group is critical.

Dr. David Hornbrook, DDS, FAACD, is privileged to instruct dentists nationwide on the latest advancements in cosmetic dentistry. He is considered a pioneer in live patient treatment education. Graduating from UCLA in 1986, he has been ranked as one of the top three cosmetic dentists in the nation by his peers. As one of less than 300 accredited members in the world of the American Academy of Cosmetic Dentistry, he holds positions on editorial boards of over 10 professional journals. He currently practices in San Diego, Calif. As the executive director of The Hornbrook Group, he brings his leading-edge program across the country to hundreds of clinicians, creating a passion for dentisty.