Creativity & Necessity - The parents of invention

WRITTEN BY

Sharon C. Siegel, DDS, MS, and

Ronald Gunderson, DDS

An overnight success has actually taken four years, work after hours and on weekends, collaboration with unlikely partners, and an investment of about five figures. From the summer of 1998 until April 2003, a team of professors noticed a need in dentistry and created a product to fill that need. CaStix® is now available for use by dentists, dental team members, and laboratory technicians. This is their story to inspire you to think about creating what you need!

In the summer of 1998, two professors at the University of Maryland, Baltimore College of Dental Surgery, noticed a missing link in the array of instrumentation used for dental cast articulation. No product was available for stabilizing dental casts together while attaching them to the articulator. Dr. Sharon Siegel, currently an associate professor at Nova Southeastern University College of Dental Medicine, and Dr. Ronald Gunderson, an associate professor at the University of Maryland Dental School, began a four-year journey to invent, patent, and market CaStix®. The goal of the new device is to improve articulation and occlusion for dental prostheses worldwide. As a woman dentist, Dr. Siegel shares her personal experience of finding her way in the world of intellectual property.

null

As a prosthodontist, dental educator, and private practitioner, I have experienced the frustration of stabilizing dental casts with the crude methods of using broken tongue blades and hot, sticky wax. Waiting for casts to dry after trimming before luting casts them together delays my sending cases to the laboratory. The laboratory loses time that could be spent waxing, casting, or processing dental prostheses. Using a Bunsen burner or a hot glue gun tends to be unwieldy, messy, and inefficient. One day, while I articulated casts for a patient, I asked Dr. Gunderson, "Isn't there a product on the market better than sticky wax and tongue blades for articulating casts?" He responded, "No, but there should be!" With that, I said, "Then we should invent a product to do just that!" Motivated by a desire for better patient care, our quest began to design, develop, and test a device and adhesive that adheres to damp casts to simplify the process.

Dr. Gunderson designed the first prototype from acrylic, naming it CaStix®. Then, we collaborated on newer, better designs with each other and individuals at the University of Maryland, as well as businesses in and around the area. We worked with faculty and staff, patent and trademark attorneys, students, businessmen, engineers, and chemists. While CaStix® is truly Dr. Gunderson's and my brainchild, the product that resulted has involved a melting pot of ideas and efforts. The entire process involved patenting and trademarking the product and starting a company called Articulation Innovations, LLC.

We learned about manufacturing processes along the way. We found a manufacturer that uses CAD/CAM to create the product mold and make CaStix®. After the initial manufacture, we tested and modified the product many times. Then, we learned about business planning, including a range of documents. Our latest collaboration was with the University of Maryland's Hinman CEO's Program and the Smith School of Business. The faculty and students have helped us learn how to be responsive with a businesslike manner in a retail world.

We didn't know it, but we were part of the "intellectual property movement" in universities around the country, which has become big business for colleges exclusive of pharmaceuticals. A conflict-of-interest agreement with the university allowed us to have a Maryland business while performing our academic duties. We also signed a licensing agreement with the University of Maryland to allow the company to sell the patented product. We now mentor other faculty members about securing intellectual property issues. The University of Maryland's newly formed Office of Commercialization and Technology involves us in regular seminars about all stages of product development on the graduate school campus in downtown Baltimore.

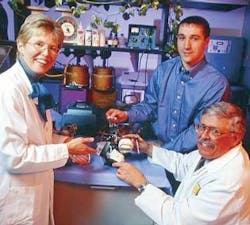

We added another partner to the company last year, Ryan Hayleck, a 22-year-old former engineering student from the Hinman CEO's Program. He has been an asset by advising us, minimizing conflicts of interest, and promoting CaStix®. As a result, Dr. Gunderson and I have been featured in Baltimore's Business Journal, have been interviewed and videotaped for the University of Maryland's Web site, and the university's School of Engineering has featured us in its promotional video.

In August 2002, we made our first online sale through our virtual store at www.castix.com. It isn't difficult to create and operate an online store, but the logistics of teaching, researching, and performing service for the university and learning about e-business has proven to be more than a 24/7 job. Just recently, the Business School at College Park engaged several bright students to help with the marketing process. Dr. Gunderson and I have begun promoting CaStix® at laboratory trade shows, most recently at New York's Lab Day East last April. I have remained an integral part of the company through my move to Florida, while Dr. Gunderson maintains most of the inventory in Maryland.

The entire process has been supported by the University of Maryland's president, Dr. David Ramsey; our departmental chair, Dr. Morton Wood; and Dr. Mike Rollor and David Marks, Esquire, from the Office of Commercialization and Technology. As a female in this process, I found that everyone I have worked with has been most supportive. The reason for this, I believe, is that I am comfortable collaborating with people and creatively finding new ways to make things work. All of my colleagues were very comfortable with me as a female in that role.

Dr. Gunderson and I have spent a tremendous amount of time after hours inventing, patenting, and managing the business matters of CaStix®. We have published three papers on the product, both research- and technique-based. Working on CaStix® has been the passion in my life (besides my family!) for the past four years. Besides the time investment, Dr. Gunderson and I each have personally invested in CaStix® to capitalize the company. The University of Maryland has invested more than twice as much in patenting fees alone. We have been advised by former businesspeople and venture capitalists about which direction the company should take. Ultimately, Dr Gunderson and I have found that we are the bottom line in testing the waters for our invention, making personal contacts, and successfully launching our product. This has been a labor of love for both of us U loving every minute of the adventure!

CaStix® Stabilization System

Directions for use ...

CaStix® is simple and inexpensive to use. The CaStix® Stabilization System includes 50 CaStix®, the adhesive, and the accelerator. Each component can be purchased separately.

1. Obtain accurate casts with bases trimmed close to equal dimensions. The casts may be slightly damp.

2. Relate the mandibular and maxillary casts in the desired interocclusal position and determine on the cast bases where the CaStix® stabilizers will be placed for maximum contact of the attachment pads. The CaStix® may be turned at an angle to accommodate various intercast dimensions. The CaStix® attachment pads do not have to be in full contact with the bases.

3. Place a small amount of the recommended high-viscosity adhesive in the location identified for the first CaStix® stabilizer. Caution: As with all Cyanoacrylate adhesives and chemical accelerators, care must be taken to prevent contact with skin and eyes. Follow the manufacturer's directions completely! If the casts are damp, first place a small amount of accelerator on the casts in the location of the attachment pads to prime the surface before applying the adhesive.

4. Position the CaStix® device onto the adhesive and spray the accelerator to produce an initial set.

5. Repeat this process for each of the stabilizing CaStix® that will be placed.

6. After the mounting stone has hardened and the casts are securely attached to the articulator, gently torque or twist the cross-arm of the CaStix® stabilizer to separate the arm from the attachment pads. The attachment pads may remain on the casts. No further preparation or cleaning of the casts is necessary.

7. The articulated casts are now ready for the fabrication of the prostheses or for further diagnostic use.

null

null

null

null

null

null

Note: After these six steps are completed, the casts are ready to use. The pads may be removed with a knife if desired.

Sharon C. Siegel, DDS, MS Dr. Siegel is an associate professor in the Department of Restorative Dentistry at Nova Southeastern University, College of Dental Medicine. She is a Fellow in the Academy of General Dentistry and the American College of Dentists. Contact her at [email protected].

Ronald Gunderson, DDS Dr. Gunderson is on the faculty in the Department of Restorative Dentistry at the University of Maryland Dental School. He is a Diplomate of the American Board of Prosthodontics. He will retire from the university on Aug. 1. Contact him at rgb001@ dental.umaryland.edu or [email protected].