How to get great X-rays from your processor

By Lloyd Luckey

Lately, the aggressive drive toward digital X-rays has dentists wondering if their processors are becoming obsolete. Before you make the plunge into digital bliss, consider the options. If you own a conventional X-ray processor, you can achieve "better-than-digital" images. A little knowledge about the processor that you own (or want to purchase) can save you thousands of dollars.

$100,000 to $150,000

Investment in conventional processor —

$3,000 to $5,000

Clean rollers and fresh chemistry deliver great X-rays — better than digital images, in my opinion — but that is not the only consideration. The difference in cost is quite astounding. If you already own your processor, the monthly expense of about $68 plus film is negligible compared to the $100,000 - $150,000 investment for digital X-rays (computers in every room, digital imaging software, licensing fees, and digital equipment). Even if you are purchasing a new processor, you still save thousands of dollars.

Theoretically, your processor should be able to give you like-new results indefinitely. Basic maintenance will keep your processor performing at an optimum level, producing high-quality X-rays every time.

All manufacturers of automatic processors recommend the same simple maintenance steps:

- Run a daily clean-up sheet as the first film of the day

- Weekly, clean the developer and fixer rollers or webs

- Monthly, soak.

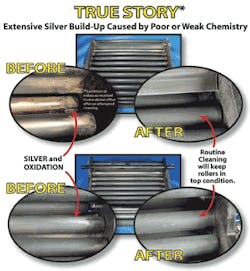

Fresh chemistry will keep these three steps to a minimum. All chemistry is not created equal! Some developers oxidize rapidly and cause a faster build-up of silver and dirt. The oxidation process is ongoing, whether you are developing film or the machine is sitting idle. The dark color of developer is a visual sign of oxidation, weaker chemistry, and poor X-rays. Developer that maintains a "lemonade" color for a longer period of time will deliver better X-rays and run cleaner in your machine.

Good chemistry has extra additives that prevent roller marks and improve X-ray drying. A little extra spent on chemistry will improve your images and shorten your cleaning time. Better chemistry also requires less replenishment, saving you money. You will save the cost of a gallon of developer and a gallon of fixer in the normal three-week cycle. That's right — the national average for chemistry change is three weeks! Chemistry costs approximately $40-$50 per month.

Daily — The daily clean-up sheet removes debris that settles on the rollers when the machine sits idle. Upon start-up in the morning, this fine debris will cause your X-ray film to appear grainy. A good clean-up sheet will guarantee clear, sharp film every time. Clean-up sheets should also be the first film after every cleaning. During a cleaning, debris is cut loose and many times is not thoroughly rinsed off. Ninety-five percent of this debris, both small and large, can be removed with a clean-up sheet. Using an exposed film is a myth. In fact, it only depletes your chemistry further. Clean-up sheets cost about $1 per use (see below).

Weekly — Weekly cleaning of the rollers, webs, and transports is needed to prevent build-up and film slippage. Cleaning as you go requires less time. A quick cleaning removes any silver or oxidation build-up. Remove the developer and fixer rollers, rinse, foam, and scrub with pad, then rinse again. This takes 10 minutes at most. Return the rollers to the machine and run a clean-up sheet. Choose a foaming cleaner that does not create an aerosol, stain, or smell bad. These cleaners are very inexpensive, costing only $2 per cleaning.

Monthly — Every month, start fresh with a good soak. A professional-strength cleaner is a good way to start over with like-new rollers. These cleaners are good for deep cleaning and removing large amounts of silver and oxidation build-up. A soak removes the silver and build-up in areas that cannot be reached with a pad and the weekly cleaners. A professional-strength soak will also clean the developer tank. The best products cost approximately $10 with no haz-mat shipping fee.

Armed with know-how and quality products, you can have great X-rays every time using the equipment you already have in your office.

Author's Note: For a free processor maintenance how-to chart, call (800) 880-0240.

Lloyd Luckey is president of SDS (Southland Distribution & Sales), a company specializing in quality radiographic products. For more information, call (800) 880-0240 or visit www.sdssouthland.com.

Dark room tips

- Every morning, drain 5-8 oz. of developer and fixer, then replenish. Replenish the same for every 30 periapical X-rays or two panoramic X-rays. (Note: Chemistry can differ greatly between brands. Be sure to check replenishment requirements for your brand. Most brands require 8 oz., but products that do not oxidize rapidly require as little as 5 oz. of replenishment.)

- Check developing time and temperature of your processor and follow the manufacturer's recommendations.

- Store solutions at room temperature. Avoid hot or freezing temperatures and direct light.

- Keep lids tightly secured on developer and fixer to prevent oxidation.

- Squeeze bottles so liquid rises to the top before capping. This reduces the amount of air in the bottle and slows the oxidation process.

- Be aware of the shelf life of unopened chemistry. Depending on brand, it can vary from six months to two years.

- Eliminate accidental light exposure to a whole box of film by using an old box for partial storage.

- Check darkroom and safelight for white light leaks. Make sure safelight bulbs are the correct wattage so the safelight lens does not peel or crack and emit white light.