The benefits of adding prosthetic-driven implant planning to your practice

The demand for implant treatments is on the rise, and so are expectations. Patients are now more informed about the procedure, and they demand results that are both highly functional and aesthetic in the fewest number of appointments possible. Fortunately, new technology has made it possible for general practitioners—who have undergone the proper training—to offer their patients the convenience of implants within their own practice.

This paper examines the value that prosthetic-driven planning brings to the implant placement process for trained general practitioners, and who own an intraoral scanner and CBCT system.

All about the Outcome

The traditional methodology behind the implant workflow involved first placing the implant in the available bone. At that point, the clinician would then determine where the crown should be positioned.

Prosthetic-driven planning, however, reverses this process with a crown-down approach. With this method, the outcome lies at the heart of the workflow, driving the process from start to finish. And by taking this approach, there are no unwanted surprises at the restorative end of the process. There’s no need to step in and salvage a situation with extensions, custom abutments and other compromises1 when it’s time to place the restoration. Instead the clinician has more predictable—and often higher quality—outcomes.

The Prosthetic-Driven Planning Workflow

1. The prosthetic-driven planning workflow starts with taking a cone beam computed tomography (CBCT) scan of the patient. The doctor uses this image to identify anatomical obstacles and evaluate bone structure, the mandibular nerve and sinuses.

2. The next step is to create a digital model, which can be accomplished in one of two ways: the clinician can use an intraoral scanner to create a digital impression, or the clinician can take a traditional impression and then scan the impression using a CBCT system.

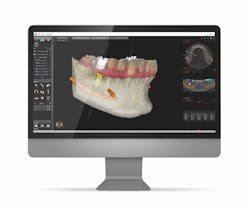

3. Then, using interactive software for treatment support, the data from the CBCT scan and digital impression are merged together. Figures 1-3.

Figure 1

Figure 2

Figure 3

What is the point of obtaining both extraoral and intraoral images? While the clinician can gain valuable insight about the mandible or maxilla, CBCT does not provide enough information about the surface detail of the teeth or soft tissues.2 When CBCT information is combined with the digital impression in the interactive treatment software, the doctor’s diagnostic capabilities are greatly enhanced, and, consequently, so is treatment planning.

At this point, the clinician can begin to plan the implant and abutment, taking into account the form, fit and function of the final restoration.

The interactive implant planning software provides multiple views, enabling the clinician to evaluate potential implant receptor sites with greater accuracy. Through the software, bone can be “removed” or displayed with transparency, which helps in determining the precise placement of implants, abutments and translucent virtual teeth in proximity to the natural tooth root structure. A virtual crown is used to guide the placement of the virtual implant for optimal aesthetics and function. This allows for well-informed conclusions to be drawn about crown-to-implant ratio; implant diameter and length; and the design of the restoration in terms of screw or cement retention.3 Figures 4-5.

Figure 4

Figure 5

The next step involves exporting the 3D data into third-party software for the design and fabrication of a surgical guide.

Thanks to the prosthetic-driven planning workflow, implants can be placed with a level of accuracy and consistency that’s hard to achieve through conventional implant placement.4 With all of that upfront information and planning, successful outcomes are much more likely to be delivered without unforeseen challenges.

It’s also important to highlight the strategic role that the surgical guide plays. However, the guide is only as good as the plan that went into creating it, and it is not a guarantee of a successful outcome but rather a safety measure and facilitator. Greater precision in the implant process is possible only with the complete evaluation of the receptor site, the implant dimensions, the abutment type and the components required to surgically complete the case. Obtaining this insight upfront prepares all members of the team for a no-surprise, outstanding outcome.5

Impact on Case Acceptance

Before patients agree to undergo implant treatment, they need to feel confident about the clinician and the diagnosis. They also want to understand the associated costs. Clear communication and education are essential in building trust and assuaging concerns. They are also key in obtaining acceptance of the proposed treatment.

A treatment plan that includes crystal-clear 3D images and a highly defined, step-by-step approach is quite compelling. It helps patients visualize their aesthetic outcome. This treatment plan delivers the message that the clinician has thoroughly thought through the process and has invested in the technology to ensure success. In addition, with a complete understanding of the patient’s anatomy and clinical situation—thanks to extraoral imaging and an intraoral scanner—the clinician can confidently estimate the costs. The prosthetic-driven planning protocol removes surprises and guesswork.

This comprehensive treatment plan engages patients and embodies the peace of mind that they are looking for.

Enhanced Communication Capabilities with the Right Technology

The clear, illustrative images obtained through CBCT scanning and the digital impression are excellent for communicating with members of the implant team.6 They greatly enhance the clinician’s ability to collaborate across the treatment network.

CBCT

CBCT scanning produces DICOM, which is a universal format and is supported by many of the 3D viewers available on the market—facilitating collaboration. There’s no need to worry that a member of the treatment network will have difficulty reading the files.

As long as the files produced are in an open format, the clinician can exchange files quickly and easily with a lab. Files with a closed format can also be exchanged. However, those files require users to stay within the closed environment, which limits their flexibility in using other partners. Closed file systems often require the user to purchase expensive software for viewing the data sets or impose click fees for accessing them.

Intraoral Scanners

Clinicians can create a digital impression with an intraoral scanner and—while the patient is still in the chair—send that information to the lab for review. If the lab wants an area to be rescanned or the proposed design to be modified, the clinician can do so immediately. There’s no need for an additional office visit, saving valuable chair time and preserving the patient’s confidence in the clinician’s methods.

The lab can also make quick evaluations and anticipate the technical complications and considerations in producing the final prosthesis. Doctors can use this information to more accurately estimate their cost and patient pricing.

Digital technology plays a key role in producing the final prosthesis. The intraoral scanner enables the clinician to use a scanbody, which is a post that attaches to the implant fixture to acquire the implant position. This provides the information required to design the restoration.

Software

Interactive software typically enables the clinician to generate an implant report to aid in the ordering of the components needed for implantation. The report can also be shared with labs and colleagues.

Increased Patient Satisfaction

Faster treatment

From the initial appointment to the final outcome, the prosthetic-driven implant workflow expedites the treatment process. Using an intraoral scanner to take digital impressions is significantly faster than traditional methods, as they eliminate the need for creating a physical model or wax-up. The implant planning software merges the files from the digital impression and CBCT scan, and the clinician can present the treatment plan to the patient—all within the first appointment. If the patient accepts the treatment plan, he/she can immediately schedule surgery.

Because files are sent electronically, there are no shipping delays to factor in. The combined use of 3D imaging technology and CAD/CAM restoration promotes the immediate loading of the restoration and saves significant time in the post-operative phase.

Greater comfort and higher quality outcomes

Since prosthetic-driven planning typically involves the use of a flapless approach, the procedure is less invasive. Patients experience less pain, swelling and overall postoperative discomfort.

Less invasive procedures lead to better restorative outcomes. “A recent study to assess prospective implant sites using panoramic radiography versus panoramic scans combined with CBCT imaging revealed that CBCT increases the accuracy of treatment planning in predicting the actual implant dimensions required at surgery. Performing a CBCT scan during the planning phase increases the accuracy of predicting implant length considerably, from 40 percent after the initial 2D scan to 69.5 percent. The overall outcome is a more predictable surgical and restorative result.”7

Cost savings

Because prosthetic-driven planning deals with digital files, there are no shipping costs to factor in for impression creation. With the extensive planning that goes into the prosthetic-driven planning workflow, there’s less chance for unintended events, which can set back the final treatment plan and substantially increase treatment costs and time.

Conclusion

With the insight obtained through intraoral scanning, CBCT scanning and the prosthetic-driven planning workflow, the clinician can place implants with a level of precision, accuracy and consistency that’s hard to achieve through traditional implant placement. Efficiencies are built in throughout the process, resulting in fewer appointments from start to finish. Intraoral scanners and CBCT imaging streamline the digital workflow with images that facilitate diagnosis, treatment predictability, patient education and surgical accuracy. The prosthetic-driven planning workflow also eliminates guesswork and increases clinician confidence. Through faster treatment times, improved patient comfort, reduced cost and higher quality, more predictable outcomes, the benefits to be gained by both the clinician and the patient are considerable.

Outstanding outcomes are attainable without prosthetic-driven planning. However, the clinician will undoubtedly discover that, when prosthetic-driven planning is part of the process, those outcomes can be delivered more quickly and reliably—and likely at a lower cost.

Why CS Solutions and Carestream Dental?

CS Solutions for Implants

CS Solutions for Implants covers the entire treatment workflow, from imaging and diagnosis, to the scanning of scanbodies, to the fabrication of the surgical guide. With CS Solutions, clinicians can obtain the precision they need to confidently plan and place implants—ensuring optimal outcomes each and every time.

Scanning and diagnosis support: From obtaining detailed 360° views of a patient’s bone morphology with the CS 8100 3D or CS 9300 extraoral imaging systems to making silicon-free digital impressions with the CS 3500 or CS 3600 intraoral scanners, Carestream Dental’s 3D imaging systems cover the entire implant process. Clinicians can see the complete picture of the clinical situation, enabling them to evaluate bone volume, mandibular nerves and sinuses, as well as the soft tissues and surface detail of the teeth. 3D data is then stored centrally in single imaging software to facilitate and expedite data management and retrieval.

- 3D planning: User-friendly and intuitive, CS 3D Imaging software takes the process of planning implants to a whole new level of efficiency and precision. CBCT and digital impression data are merged automatically with little-to-no manipulation required. Clinicians can add virtual crowns and select from a comprehensive library of implants (from more than 60 manufacturers) to virtually place implants in the appropriate axis and then add abutments. They can also create their own implants and manage their own library. Clinicians can view the location of the proposed implant in relation to the bone and restoration—on the same screen—to ensure optimal positioning and aesthetic results.

- Placement: To create the surgical guide, clinicians can simply export the 3D data into their preferred third-party surgical guide software thanks to the open file format. Clinicians can easily generate implant reports—again, with a single click—which helps them effectively prepare for surgery and share information with labs, colleagues and patients.

- Restoration: The digital workflow continues in the restoration phase, as the clinician uses the intraoral scanner to acquire the implant position and create the final restoration. Because CS Solutions for Implants produces open files that can be used in third-party CAD software, clinicians can use the lab of their choice to create implant-borne restorations. Labs, in turn, have flexibility in the CAD design software they use. As a result, doctors can enjoy an unlimited range of potential partners to choose from.

Unique Collaborative Capabilities

With CS Solutions for Implants clinicians can:

- Exchange files effortlessly with the implant network to speed up workflow.

- Enable the implant network to open 3D files simply with the CS MeshViewer and CS 3D Imaging software.

- Integrate the implant network and CAD/CAM workflow easily with versatile 3D file format options: .STL, .PLY, DICOM.

User-Friendly and Highly Intuitive Software

- The software automatically aligns the digital impression with the CBCT scan so that clinicians can obtain the virtual setup with little-to-no manipulation.

- Intuitive tools enable clinicians to make alignment adjustments manually if needed.

- Clinicians can generate an implant report in one click to order the components needed for surgery and share with labs and referrals.

- Easily export both CBCT data (DICOM) and digital impression files (.STL) into the following third-party software for surgical guide fabrication: Simplant, Implant Studio, NobelClinician, Blue Sky Bio, 360 Imaging,3DDX, coDiagnostiX

Enhanced Patient Communication and Education

CS Solutions for Implants enables clinicians to help patients understand the entire implant process from start to finish, address their concerns and build their confidence in the treatment plan. For example, using CS Solutions’ interactive planning software, clinicians can show their patients images of their crown build-up. Clinicians can then assure them of the higher quality outcome that results from using the prosthetic-driven planning workflow: “If I place a standard abutment, not an angled abutment, you will have the strongest, easiest and most cost-effective implant option.”

Learn more about CS Solutions for Implants here.

About Carestream Dental

From the first dental radiographic film and the world’s first digital intraoral sensors to cutting-edge low-dose 3D imaging technology, Carestream Dental consistently invests in research and development to continue innovations in dentistry that better address and anticipate the needs of dental professionals across the globe.

Its primary goal is to help dental practices deliver diagnostic excellence through the use of humanized technology and streamlined workflows. Its product portfolio includes specialty-specific practice management software; imaging software with specialty-specific workflows; intraoral digital impression systems; panoramic and cephalometric imaging; and 3D imaging systems, as well as other intraoral and extraoral imaging equipment.

For more than 100 years, Carestream Dental has provided dental professionals across the globe with the imaging tools and information they need to work more efficiently and better serve their patients. Currently, you can find Carestream Dental products in 7 out of 10 dental practices worldwide and in over 108 countries. Discover why those practitioners chose Carestream Dental: visit carestreamdental.com.

Sources

1. Jansen, Curtis. “Restorative-driven implant therapy,” CAD/CAM, North America Edition, Vol. 4, Issue 1, 2014, p. 21.

2, 3. Ganz, Scott D. “The Next Evolution in CBCT: Combining Digital Technologies,” https://eliezerganon.wordpress.com/2014/08/02/the-next-evolution-in-cbct-combining-digital-technologies/.

4. Abai, Siamak and Dalmau, Zach. “Immediate Final Restorations: A Comprehensive Digital Approach to Implant Dentistry,” http://glidewelldental.com/education/inclusive-dental-implant-magazine/volume-4-issue-3/immediate-final-restorations/.

5, 6. Ganz, Scott D. “The Next Evolution in CBCT: Combining Digital Technologies,” https://eliezerganon.wordpress.com/2014/08/02/the-next-evolution-in-cbct-combining-digital-technologies/.

7. “Diagnostic imaging in clinical practice,” Science First, Volume 3, Issue 2, 2015, p. 12.