Choices Abound

by Andre Theberge, RDT, CDT

As dental implant usage grows, so do the many types of fixed restorative options for dentists and their patients.

Today, dentists are able to restore for function as well as esthetics. Consequently, implants are a key option when restoring missing dentition. As dental-implant usage grows, so do the many types of fixed restorative options.

Implant abutment options

There are three main categories of abutments used in the fabrication and restoration of implant dentistry -

➊Implant manufacturer-produced stock abutments;

➋Laboratory-fabricated, custom abutments; and

➌ CAD-CAM custom abutments, the most recent addition.

Let’s explore each of these abutment categories. Remember the benefits and concerns of each type available in restoring implant cases.

➊ Implant manufacturer-produced stock abutments

(See Fig. 1.) This class of abutments is an implant abutment that is pre-machined by the manufacturer to meet their standard specifications. They are normally manufactured employing machined titanium. Recently, however, there have been strides made to integrate zirconium, and in the case of Implant Innovations Inc./3i, a gold-colored, TiN-coated abutment has been added to the armamentarium of stock abutments, which has been developed to minimize gingival discoloration. Benefits associated with the use of these types of abutments include a proven track record, because they have been used the longest in the restoration of implants, cost, and the convenience of ordering them in advance. The concerns with this class of stock abutments are that they have limited emergence profiles, angulations, and sizes. In addition, the use of the more esthetic zirconia material is somewhat limited.

➋ Dental lab-fabricated custom abutments

(See Fig. 2.) As implant popularity increased, the need for a customized implant abutment arose. This is where dental laboratories stepped in to fabricate a custom abutment that was waxed, cast, and finished to provide the most ideal situation for both function and esthetics. These custom abutments were fabricated with high-noble or noble alloys possessing the strength necessary to support the desired implant restorations. The major benefits of this class of abutments are the ability to achieve an optimal emergence profile, angulation, and prep design to achieve the desired result. In addition, it allowed restorative dentists to use any brand of implant system. The major concern with the lab-fabricated custom abutment has been the skill level and experience of the dental laboratory fabricating the abutment. It requires the knowledge and technical expertise to get a porosity-free casting so as not to impair the strength and integrity of the completed implant restoration.

➌ CAD-CAM Custom Abutments

(See Figs. 3a and 3b.) In 2001, a new class of custom implant abutments became available. Nobel Biocare developed custom implant abutments using CAD-CAM technology. This system, of which Drake Precision Dental Laboratory was a Beta test site, enabled the dental laboratory to scan and design the abutment and have the abutment milled at the Nobel Biocare manufacturing facility. The system has been enhanced with the addition of the new Procera Forte (Nobel Biocare) scanner (see Fig. 4) and with the ability to produce the abutment out of both titanium and zirconium.

Other companies have developed their own CAD-CAM custom abutments. Implant Innovations Inc./3i has developed Encode, a titanium custom abutment designed by the laboratory and milled at the manufacturing facility. Drake was a Beta test site for this product, too.

Most recently, Atlantis has introduced a CAD-CAM titanium and zirconia custom abutment. CAD-CAM custom abutments are generally fabricated out of two materials: titanium or zirconium. The major benefit of the titanium custom abutment is the biocompatibility of the material. In addition, the abutment is computer-designed and machine-milled to obtain a precise fit. Other benefits include adaptability with most of the popular implant systems as well as a cost comparable to lab-fabricated custom abutments. The CAD-CAM zirconia custom abutment is rapidly becoming more popular. This is primarily because of the enhanced esthetic possibilities of using a metal-free abutment in conjunction with a metal-free restoration. In addition, benefits of the zirconia abutment are a precise fit, thanks to machine fabrication, and compatibility with most popular implant systems.

Lab-fabricated implant restorative options

The final step in the restoration of an implant is the proper selection of the type of fixed crown or bridge needed to complete a functional and esthetic result. The fixed restorations fall into two categories: those containing metal, and metal-free restorations. Let’s explore the options available to dental practitioners in the restoration of implant cases.

Porcelain-fused-to-metal implant restorative options

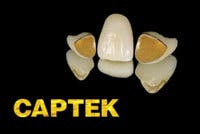

(See Fig. 5.) The standard for restorative dentistry for more than 50 years is also the most prescribed in the world of implant restorations. At Drake, implant crowns and bridges are of three varieties; porcelain fused to a white high noble alloy (50 percent gold and 35 percent palladium), porcelain fused to white noble alloy (75 percent palladium and 6 percent gold), and most recently, porcelain fused to Captek (Precious Chemicals, Inc.), a high noble, rich yellow-gold-colored substrate. The primary reasons for using the metal-containing restorations are strength and durability. But, with the growing popularity of Captek, we are able to achieve the strength needed for success and the additional benefit of excellent esthetics, a result of the rich yellow color of the Captek that mimics the honey-colored hue of natural dentin in combination with the highly esthetic modern ceramic materials available. Using the above restorations in conjunction with either titanium or gold-colored implant abutments allows a dental team to provide patients with highly proven, functionally esthetic results.

Metal-free implant restorative options

(See Fig. 6.) Since the mid-’90s, the evolution and popularity of metal-free crown and bridge restorations have made a major impact on the world of restorative dentistry. Implant restorations are no exception. With the advent of zirconia abutments, the use of metal-free crowns and bridges used to restore implants has been on the rise. In fact, the number of metal-free crowns and bridges used in restoring implants is in excess of 30 percent. The three most popular metal-free brands prescribed for implant restoration are Nobel Biocare’s Procera Zirconia Crowns and Bridges, 3M ESPE’s Lava Crowns and Bridges, and Ivoclar Vivadent’s IPS Empress, or the new IPS e.max. The Procera, Lava, and e.max use a high-strength zirconia substructure combined with specialized ceramics that provide extremely strong and esthetically pleasing restorations. These materials can generally be considered for restorations over metal and zirconium abutments. The Empress crown, the restoration credited with starting the Esthetic Revolution, is a leucite-reinforced ceramic that meets the most demanding esthetic requirements of patients.

Conclusion

The use of dental implants has risen exponentially during the past 10 years. Communication must exist between the dentists placing the implants, practitioners responsible for restoring the implants, and dental laboratories that provide the finished abutments and restorations. Clinical teams must select a laboratory that is educated in the nuances of all implant systems and that has the technical ability, latest technologies, and ability to provide the products best suited for the end result: satisfied patients. ■

Andre Theberge, RDT, CDT

Theberge is laboratory manager at Drake Precision Dental Lab in Charlotte, N.C. He attended college at George Brown College in Toronto, Canada, and began his career as a private technician. Reach him at (800) 476-2771.