Has 3-D printing for the dental office arrived?

3-D printing isn't just for the lab anymore. The Form 2 3-D printer from Formlabs can be used in dental offices for applications such as creating study guides, surgical guides, and bone models.

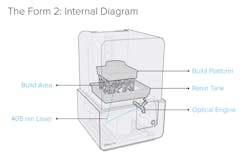

The market for 3-D printers has exploded recently, offering consumers a greater number of choices, including more affordable choices. Last year, Formlabs Inc. introduced its newest and most advanced 3-D printer, the Form 2. Shortly thereafter, Formlabs entered the dental industry with the introduction of a biocompatible resin designed for dental implant surgical guide fabrication. The Form 2 is a stereolithographic 3-D printer that uses a computer-directed laser to cure a photosensitive resin, layer by layer, to create complex, three-dimensional objects (figure 1).

Additive manufacturing, or 3-D printing, technology is not new to dentistry. But although it has taken a foothold in the dental industry over the past few decades, industrial 3-D printers from companies such as Stratasys, 3D Systems, and EnvisionTec have historically cost tens of thousands of dollars. Because of this, the technology has been limited to large commercial dental laboratories until now.

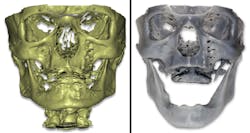

The Form 2 is a desktop version of this technology with a price that is accessible to individual dentists or dental offices. In dentistry, common applications for this technology include creating study models from intraoral scans, creating surgical guides using implant planning software, and printing bone models from CBCT scans (figure 2).

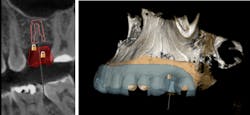

One thing that sets Formlabs Inc. apart from other desktop 3-D printing companies is its focus on the dental industry with the introduction of the Dental SG resin (figure 3). Dental SG resin is a Class I biocompatible resin that complies with USP Class VI and ISO 10993-1 standards and is designed specifically for surgical guide fabrication. The resin is also unique in that it can be autoclaved for sterility before surgical procedures. (1)

Using this printer in combination with implant planning software allows dentists to plan and fabricate highly accurate surgical guides in the office for a fraction of commercial system prices. In addition to some of the aforementioned applications, future applications might include clear aligner therapy and possibly partial and full dentures.

How does it work?

To design your own surgical guides, you'll need a CBCT scan and an intraoral scan of the patient, or scans of dental casts or models. CBCT scans should be in DICOM file format, while intraoral scans should be in STL file format. Open software, such as Blue Sky Plan (Blue Sky Bio), 360imaging, or CoDiagnostix (Dental Wings), can be used to merge the CBCT scan and intraoral scan, plan the implant position, and design the surgical guide.

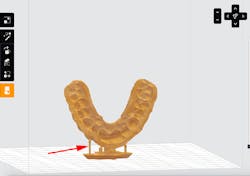

Many factors in the design process can affect the final accuracy of the guide. To accomplish this process with consistent accuracy, you need to have a thorough understanding of the implant planning software and factors that affect guided surgery and a basic understanding of CAD technologies (figure 4).

Another option is to use a laboratory that offers guide planning services such as 360iPrint (360imaging) or the SICAT DigiGuide service (Dentsply Sirona) (figure 5). With these services, labs will offer treatment planning and design advice and verify the accuracy of the guide file. Next, the lab will send the guide file back to you to be printed locally. These services offer a nice middle ground for affordable pricing and quality control.

Once the guide is designed, the guide file can be imported into the Formlabs Preform software for printing. The Preform software allows you to design the file (print orientation, support design, etc.) for printing and send the file to the Form 2.

Supports are the structural link between the flat surface of the build platform and the complex-shaped surgical guide (figure 6). You should not place supports on the intaglio surface or in the guide tube(s) because the supports leave small areas of distortion that may affect the fit of the guide. Although there are methods for printing with minimal or no supports, these methods are technique sensitive and should be reserved for advanced users. The orientation and support of the guide file will translate directly to the accuracy of the print. Once you are satisfied with the print design, the file is sent to the printer and the printing process can begin. It usually takes about three hours per guide, depending on the design.

After the guide is printed, it must be cleaned with isopropyl alcohol, dried, and polymerized under UV light. Then the supports can be removed, and the guide tube can be inserted. Finally, the guide should be autoclaved in preparation for the surgical procedure. Figure 7 illustrates the color changes that occur during the post-processing workflow.

Should you adopt this technology?

This is a personal decision that depends on your desire to embrace and learn new technology, your time management needs, and additional factors. While this technology is proven and reliable, there is a learning curve similar to that of other technologies in dentistry. We have attempted to list some of the pros and cons of both this system and 3-D printing in the dental office below.

Pros

• Affordable price

• Print quality close to industrial 3-D printers

• Open system that can be integrated with different digital solutions

• Wireless, Ethernet, and USB connectivity

• Touch screen display

• User-friendly software

• Compact footprint ideal for the dental office

• Great support team with a commitment to product improvement

• Patient perception of cutting-edge technology

Cons

• Requires a base knowledge of CAD technologies and 3-D printing

• Requires a technical knowledge of implant planning software and factors that affect accuracy

• Smaller build volume than industrial machines

• 3-D printing is still a relatively slow process

• Requires time and additional materials for post-processing workflow

References

1. Whitley D, Bencharit S. Digital implantology with desktop 3-D printing. https://formlabs.com/digital-implantology. Formlabs white paper. Published 2015.

2. Whitley D, Eidson RS, Rudek I, Bencharit S. In-office fabrication of dental implant surgical guides using desktop stereolithographic printing and implant treatment planning software: A clinical report. J Prosthet Dent. In press.

Editor's note: This article first appeared in Pearls for Your Practice: The Product Navigator.Click here to subscribe. Click here to submit a products article for consideration.