The $10,000 question

By Jeff Carter, DDS

I have tried for five years to determine the best CCD (charged coupling device) or CMOS (complimentary metal oxide semiconductor) digital radiography sensors or combination of sensors. I have conversed with doctors, salesmen, technicians, and dental integration specialty companies. You have asked me countless times what I thought is the best sensor, I have asked you countless times what has worked well in your office or at least in other colleagues' offices, and I still don't know what to tell you. For example, a recent advertisement claimed 45,000 practices use this company's sensors everyday. I assume that includes worldwide usage because I can't remember the last time I encountered a user of this company's sensors in the United States.

I was hopeful the costs for "instantaneous" radiographic image capture would greatly reduce over time as they have for computers, LCD monitors, digital cameras, and almost all other technological products. One hope for a cost-reduction was the CMOS sensor which is easier to produce than the CCD sensor. Unfortunately, the image quality has issues and the CMOS cost reduction has never come to fruition. Hence the big question — Will you pay $10,000 for one CCD or CMOS sensor? It is my concern that if you do, you will probably experience fluctuating image capture, hardware and software issues, and support problems. I hope this is not the case, but this is the type of feedback I hear on a regular basis.

The one bright spot would be endodontic practices. I have heard and observed many endodontists satisfied with their CCD or CMOS sensors. Schick is the sensor vendor most frequently mentioned in association with endodontic offices.

For what it is worth, I would not recommend exclusive reliance on CCD or CMOS sensors to capture all radiographic images in a general dentistry practice. My observation is that the exclusive use of CCD and CMOS sensors in general practice applications is not occurring successfully in significant numbers, at least in the United States. Why?

Cost — A general practitioner employing two full-time hygienists would need at least two sets of three different-sized sensors to take full-mouth series, and one panoramic sensor. Unless you purchase multiple sensors, it does not make sense to pay top dollar for "instantaneous" image capture and then have to wait five minutes for a shared sensor from the hygienist. If CCD or CMOS sensors average $10,000 each and the panoramic CCD sensor is $20,000 to $30,000, a general practitioner is facing a substantial investment to make the switch from film to CCD.

Integration issues — Unlike the digital camera which you can purchase off-the-shelf, shoot a few photos, connect a USB cable to your computer, and easily download images into a $50 software program, the CCD or CMOS sensor integration is not so simple. Standard USB computer interfaces do not ensure consistent capture of CCD or CMOS images. Sensor vendors deliver their products and then do not typically participate in hardware set-up and installation of products that allow you to utilize their sensors. What scares me even more is that some of the best dental integration companies have backed away from reselling or even recommending any CCD or CMOS sensors. They are leaving that decision up to you, who knows much less about this subject than they do.

Technique issues — The CCD or CMOS sensors are rigid, thicker, and have a cable attached that results in increased difficulty in sensor positioning and discomfort for the patient. The wireless Schick CMOS sensor eliminated the cable and now includes a battery pack.

In my opinion, Gendex DenOptix and Air Techniques Scan-X phosphor plate systems are superior products, and I do recommend their use in general dentistry practices as a replacement for film-based radiographs. Why?

Although you must scan the plates and capture is not instantaneous, phosphor-plate scanning systems provide a more reliable and consistent image-capture medium than CCD or CMOS. The phosphor plates are flexible, nearly indistinguishable from film, and are not technique-sensitive. The integration of these systems is not difficult and is similar to connecting to a flat-bed scanner and associated software to your home computer. The cost comparison to CCD or CMOS is striking. For approximately $20,000, you can get a scanner, associated software, and multiple phosphor plates of all corresponding film sizes including panoramic. You can make the argument that more labor is involved with the scanning process and thus you must factor that into the cost differential with CCD or CMOS. That is true, but that also would have to assume flawless and trouble-free image capture with CCD or CMOS.

I propose the following to help us answer the $10,000 question: If you are exclusively using CCD or CMOS sensors (i.e., film use only as a back-up) in your practice to take bitewings, periapicals, and panoramic films, please e-mail me at [email protected] and respond to these questions:

- Which sensor and how many sensors do you have?

- What is the total approximate cost of the sensor package you purchased?

- Give a brief accounting of any capture, software, or hardware compatibility problems with your system.

- Would you or would you not recommend your sensors and integration strategy to other practices? Why or why not?

If you have a financial connection to any these products, please note the relationship in your e-mail.

If your practice utilizes a phosphor-plate scanning system (ie., DenOptix or Scan-X) for all radiographs and you do not use any film other than a back-up system, please respond to these two questions in e-mail to [email protected]:

- Which scanning system do you utilize in your practice?

- Would you or would you not recommend your system to other practices? Why or why not?

I promise all your e-mail responses and addresses will be kept confidential and will not be used for any marketing purposes.

In an attempt to capture (sorry for the pun) all sides of this issue including giving voice to the hard-working, innovative people in the industry making a good-faith effort to bring CCD and CMOS radiographic technology to the dental market, I posed four questions to John Smithson and Erich Bangert of Sirona. Smithson is director of marketing for Sirona's imaging products. Bangert, based in Germany, is manager of marketing and sales for the USA, Canada, and British Isles.

Dr. Carter: Why has the cost of the CCD (or CMOS) sensors remained at or near the $8,000 to $10,000 price range in comparison to many "high-tech" products that seem to constantly drop in price?

Bangert: Digital radiographic medical imaging has been in common use in dentistry for just over 10 years. The prices for CCDs have gone down approximately 25 percent during these years. The performance (quality, durability, etc.) in the same period has dramatically improved. Larger price reductions, however, as seen in the PC world, digital cameras, and DVD equipment are unlikely to happen soon. The total market for medical radiographic imaging sensors (which includes dental) is too small to generate economies of scale.

The high standards of digital imaging also require highly specialized manufacturing knowledge. A single intraoral radiographic image displays between 1.5 and 2.5 million pixels, and a panoramic image (depending on the specific program) between 4.5 and 19 million pixels. A pixel is the individual element on the screen that makes up an image. Since each pixel in a sensor can be active, it offers the potential of actually surpassing film in all its relevant values.

For significant price breaks to occur, worldwide annual sensor sales for digital X-ray would have to quadruple.

Dr. Carter: What aspect of the CCD technology requires the sensors be rigid and relatively thick compared to film or phosphor plates? Readers might find a brief description of the manufacturing process enlightening.

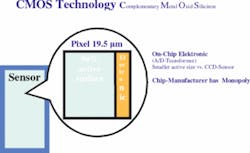

Bangert: Two types of sensor technology are established on the world market — the CCD (Charged Coupled Device) and the CMOS (Complementary Metal Oxide Silicon). CCD and CMOS differ considerably in terms of concept and technical design features.

Therefore, one reason for sensor inflexibility is the construction. Bending the sensor would damage the electronics, ceramic, fiberoptics, or the scintillator. Alternatively, an advantage of rigid sensors is their use in treatments requiring precise measurements such as endodontics. Film or phosphor plates can and will be bent in certain situations distorting the image. To avoid distortion as the result of bending, holder systems for films and sensors can be used. The sensor and the tube head are aligned parallel (see box above).

The perceived disadvantage of sensor inflexibility becomes an advantage for the operator and the patient.

Dr. Carter: Why does there continue to be feedback that CCD-captured images fluctuate in quality? Is there instability in the capture process, or is it the combination of the many varied components that may comprise a practice's computer network?

Bangert: The quality of a sensor image is constant. X-rays do not harm or damage the sensor over time. The electronic performance of the CCD is absolutely predictable. Quality fluctuations are always assignable to handling, surrounding equipment, or software. The X-ray unit also impacts the image quality. An X-ray generator using the DC technique will produce sharper, more brilliant images with lower exposure times than an AC X-ray generator.

Dr. Carter: What is your recommendation as the best configuration to capture CCD images to ensure consistent image quality and minimize hardware and software system maintenance problems?

Bangert: The best integration solution is a local office network with a dedicated server and as few interfaces between the CCD and monitor as possible. The solution for using all of the organizational advantages of digitalization in a practice is interconnecting the PCs and imaging components to form a network. A brilliant feature of Sirona digital X-ray is that all image acquisition modules, whether intraoral or panoramic, are fully networkable, i.e. they can send their image data over the network and receive commands directly, just like computers. That reduces the risk of malfunction dramatically.

I would like to thank Eric for his answers and John for arranging this input for us. An interesting distinction Bangert and Sirona are making is that the use of networkable acquisition modules to connect directly to the CCD sensor (versus a USB connection directly to the operatory PC) has yielded higher quality and more consistent images.

Please help with us with your feedback and look for a complete analysis and accounting of any responses I receive in the next issue of Dental Equipment & Materials.

About radiation

Single-pulse radiation (AC): In these technically less sophisticated systems, the voltage oscillates between 0 and 70 kV 50 times per second. However, only the radiation in the range of 50 to 70 kV is actually relevant for imaging purposes. In other words, during each pulse, the patient is exposed to low voltage radiation which delivers no diagnostic information. This radiation is either absorbed or is scattered by the patient's facial tissue.

Multipulse radiation (DC): These sophisticated systems generate a constant voltage of 60 kV (or 70 kV). This results in constant radiation quality. For example, the image quality of the HELIODENT DS 60 kV (Sirona) is on a par with that of a 73 kV single pulse unit.

The benefits:

- In comparison with single-pulse systems the proportion of "soft" radiation is reduced by up to 20 percent.

- Shorter exposure times which are ideally suited to the very short exposure times used in digital radiography.

Dr. Jeff Carter is co-owner of the Practice Design Group, based in Austin, Texas. PDG specializes in providing architectural interior design and equipment, and technology integration servicers to dentists nationwide. Dr. Carter may be reached at (512)295-2224 or by email at [email protected].

Paralleling technique

The paralleling technique has become the standard for intraoral X-ray diagnostics. It requires a film or sensor holder which is centered precisely on the X-ray beam emerging from the tubehead. By using a beam limiter on the tube, it is possible to reduce the exposed area to approximately the same dimensions as the film or sensor. The film or sensor is placed at a 90-degree angle to the central beam and parallel to the tooth axis. The image is enlarged but not distorted. The exposure is reproducible and precise measurements are possible.

- active surface is almost the same size as the sensor.

- system is modular, expandable, and network-capable

- connection to USB acquisition module or to network-capable acquisition modules

- each additional X-ray station is compatible with existing X-ray stations (this equals lower capital outlay).

- the basics of converting X-rays to electrons are the same

- the image-acquisition electronics is accommodated alongside the sensor chip

- lower-price stand-alone solution

- USB image acquisition module is the only option

- each additional X-ray station necessitates a considerable capital outlay.