The Apollo e.Light

The light-emitting diode (LED) - the new curing standard

One of today's most controversial topics is the proper polymerization of light-initiated materials. Due to the large number of techniques, material and equipment choices available, curing composites has become a challenge. With multiple-curing modalities, including fast curing, slow curing, soft curing, and pulse curing, the challenge is determining which methodology best suits your practice and ensures the proper polymerization of the materials you use.

To add to these complexities, some manufacturers are beginning to use photo-initiators that peak in different areas of the light-energy spectrum. The concern with this variable is that some composites may not polymerize quickly with the spectral output of some curing lamps. Many lamps limit their output energy to the range of the most frequently used initiator, camphorquinone (470 nm). Many - even most - composites use camphorquinone at present, but some do not.

While some lamps offer lower power with a wide spectral range, others output high power in a narrow bandwidth, making the curing of the composite efficient, but limiting the number of composites which may cure rapidly. The Apollo Elite and 95E Lights manufactured by D.M.D., Inc. offer multiple tips to ensure proper polymerization in different parts of the spectrum.

An additional variable common to almost every curing light is heat, which is present as a result of light energy output in the infrared range. Heat may add the unwelcome potential clinical effect of insult or even permanent damage to the pulp or surrounding soft tissue.

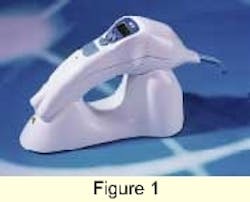

Many of these concerns have been addressed by the development of a new type of curing lamp. The cordless, light-emitting diode Apollo e.Light (Figure 1) brings revolutionary features to composite curing. It has been designed to set the standard of care and make the polymerization of photoinitiated dental materials easy and predictable for any dentist - with any composite (Figure 2). The cordless, lithium ion, battery-powered diode light polymerizes most composites in six seconds with no heat. Apollo e.Light's light-emitting diodes produce light in the visible light spectrum, from 410-490 nanometers. This spectral range ensures the activation of all photo-initiators used in dental resin (Figure 3).

The curing time, energy output, and initiation of composite polymerization are controlled by easy-to-use software. Several curing modes, including pulse cure, ramp cure, etc., contribute to the remarkable versatility of the Apollo e.Light (Figure 4). The cordless Apollo e.Light's battery is designed to last through a typical day of curing in the dental office, and is recharged on a base stand (Figure 5). The comfortable hand-held light weighs only 3/4 of a pound and a power cord is available, should it become necessary to use electric power. With this feature, the dentist is never without the ability to cure composite.

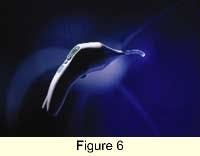

The light-emitting diode Apollo e.Light provides the ideal curing light with no heat output (no concern with pulpal temperature rise), no bulb changes (ever!), cord-free delivery with a handle that weighs less than one pound. The Apollo e.Light assures fast, safe, efficient, and worry-free curing of photo-initiated dental materials. It is sure to set the standard for the next generation of curing lights. The Apollo e.Light: it's time to practice a whole new kind of dentistry (Figure 6).

For more information, contact

Dental/Medical Diagnostics, Inc.

6416 Variel Avenue

Woodland Hills, CA 91367

(800) 399-0999 fax (818) 595-0226 www.dmdcorp.com