Save time and money with these X-ray tips from Carestream Dental: Ask the Expert for March 2011

Ask the Expert for March 2011 from Carestream Dental

Christopher A. Warren

Technical Support Engineer

Imaging Consultant

Carestream Dental

A division of Carestream Health, Inc.

Technical Support Engineer

Imaging Consultant

Carestream Dental

A division of Carestream Health, Inc.

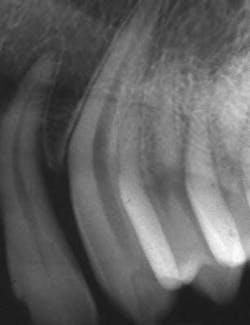

Last month we asked you to Diagnose the X-ray below and send in your answers on what you think the operator may have done wrong. Today we provide you with the image’s diagnosis!This month we did not receive a correct diagnosis to February’s X-ray image. Be sure to send in your diagnosis for this month’s Diagnose the X-Ray for a chance to win!

X-ray answerThere were several contributing factors that created the exposing and processing problems found in this image. The overall dark tone, or lower contrast to this image, is the result of the image being overexposed. There are also two abnormal lines found on this film that are the result of processing problems. The horizontal, narrow, slightly curved light density lines are scratches caused when the emulsion was pinched and ripped from the film base during processing. This is likely due to an automatic processor rack or roller being out of position. The angled vertical lines, considered roller marks, are caused when the film turned (skewed) slightly during processing. Turning of the film can also be the result of a rack or roller being out of position. The nature and directions of the artifact scratches and roller marks would prove that this type of processing problem is unique to the roller transport process.Tips and TricksIn order to avoid this problem, I recommend the following:

- In this situation, a rack may have been out of alignment or a damaged roller may need to be replaced. To correct the film scratches during processing, a very close examination of the racks and rollers are required.

- Image density and contrast quality can be improved by evaluating and adjusting the exposure technique.

- Improper film and screen combinations can cause dark films (or very light films).

- Film jams do happen occasionally. If you hear a clunking noise, a damaged drive gear may need to be replaced.

- Regular processor cleaning and use of KODAK Roller Transport Cleanup Film will greatly reduce processing problems.

- Poor quality or exhausted chemistry often causes films to transport incorrectly. It can also lead to dirt and debris accumulating on the rollers, which can scratch the film as it makes its way through the processor.

- We always recommend the use of KODAK READYMATIC Fixer and Developer in automatic roller transport processors as it is specially formulated to improve film transport.

What did the operator do wrong to achieve this image? Click here to answer.Be sure to look for the cause of the problem and Chris’s recommendation in our next issue!Contact usHave a question or concern about your KODAK dental film? If so, contact Chris.Looking for an authorized dealer?Need more information about KODAK dental film, call (800) 933-8031 or visit www.carestreamdental.com.© Carestream Health, Inc.Readymatic is a trademark of Carestream Health.The Kodak trademark and trade dress are used under license from Kodak.