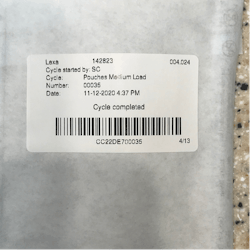

Before I began planning this remodeling endeavor, I attended an “OSHA and Infection Control” course by India Chance, RDH. She said all of the information that is required is on our sterilization bags. I realized that although my protocols are pretty good, they were far from perfect. India mentioned in her course that the following is included on our sterilization bags:

- Date

- Initials of the person who sterilized the instruments

- Sterilization cycle

- Which autoclave was used (if multiple ones are used in the practice)

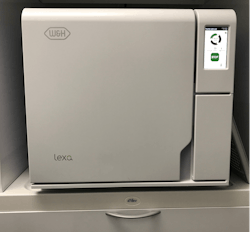

The Lexa autoclave is large enough to house my restorative cassettes, and it has innovative technology to optimize infection control, including a HEPA filter that allows only filtered air into the chamber and a single-use water system. In this system, clean water is only used once; used water is contained separately in the unit.

In addition, Lexa is a smart autoclave, because it is connected via Bluetooth to a printer that will print all of the information that should be on our sterilized cassettes and bags for optimal compliance (see figure 3). You can also connect to Lexa via an app so that you can monitor your sterilization cycle or even begin one remotely! Information about the sterilization cycle can also be stored via USB within the unit and saved for future reference.If, for some reason, a cycle were to fail a spore test or my weekly monitoring test failed, I now know how many instruments were in each cycle and how to accurately identify them. I feel so much more confident in my compliance and appreciate the innovations in infection control.

Pro tip from India Chance: Use a felt-tip pen on the tape of wrapped instruments or on the folds of sterilization bags. This ink doesn’t bleed. Make sure that if you mark your sterilization bags, place the marking on the bag exactly as directed by the instructions for use (IFU) to avoid compromising the pouch.

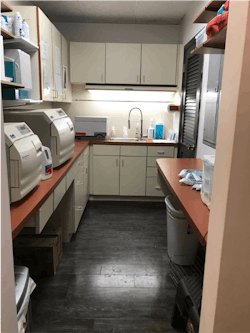

I worked with Patterson Dental to create a stericenter with an improved workflow, efficiency, and safety that also fits within the footprint of my existing space. While I am pleased with the outcome of the stericenter (figure 4),I’m overjoyed that regardless of how busy my office is or what time of day it is, the stericenter always looks spotless. There is a place for everything! I particularly appreciate the workflow; anyone can walk into the stericenter and know which part of the sterilization process an instrument (or cassette) is in, based on where it is located. Someone can continue the process where the previous person left off without missing or repeating a step. Moreover, my instruments have never been more properly cared for. My handpieces are being properly lubricated, and cassettes are being properly dried prior to and after sterilization. Another significant outcome is that this new workflow prioritizes safety for my staff.

Related articles

- One of my favorite things right now: Carbon Nitrile Gloves from Cranberry

- One of my favorite things right now: Airflow Prophylaxis Master

- One of my favorite things right now: Skyce from Ivoclar Vivadent

- One of my favorite things right now: Custom composite shade tabs

Editor’s note: This article first appeared in Through the Loupes newsletter, a publication of the Endeavor Business Media Dental Group. Read more articles at this link and subscribe here.

Pamela Maragliano-Muniz, DMD, is the chief editor of DentistryIQ and editorial codirector of Through the Loupes. Based in Salem, Massachusetts, Dr. Maragliano-Muniz began her clinical career as a dental hygienist. She went on to attend Tufts University School of Dental Medicine, where she earned her doctorate in dental medicine. She then attended the University of California, Los Angeles, School of Dental Medicine, where she became board-certified in prosthodontics. Dr. Maragliano-Muniz owns a private practice, Salem Dental Arts, and lectures on a variety of clinical topics. You may contact her at [email protected].